As the manufacturing sector evolves, industry leaders adopt new technologies. One of the most commonly used technologies is the CNC machine. It helps to create durable products, like auto parts, artificial joints, and aircraft components.

However, in the CNC industry, these machines don’t work independently. This is the reason manufacturers depend on skilled machinists and techniques to handle different kinds of machines, like the following:

Table of Contents

1. CNC Plasma Cutter

A CNC plasma cutter delivers accurate cuts. It often uses electrical discharge arcs, such as plasma torches, so as to melt materials and ionize air where those arcs strike.

Because it works through electrical arcs, the process only applies to electrically conductive components. Its applications include scrapping and salvage, fabrication shops, automotive repairs, and automobile manufacturing.

2. CNC Grinder

CNC grinding machines come in varieties, with surface grinders and cylindrical grinders being the most common. CNC grinders remove materials automatically through grinding wheels so as to improve surface finishes as well as meet tolerances, which aren’t possible with a standard tool on a lathe or milling machine.

Generally, a surface grinder works on a flat surface so as to create a smooth finish to ensure flatness and accuracy of very critical dimensions. On the other hand, a cylindrical grinder comprises a spindle head, which rotates and rotates a workplace as the grinding process goes on to make different configurations, like steps, grooves, and tapers.

3. CNC Mill

This machine uses cutting tools so as to remove materials from a workpiece and shape it to the required specifications. Basically, the workpiece is held in place while the machine removes materials.

A CNC mill may have different tools for cutting. Each has a unique purpose. Examples of these cutting tools include the following:

- Face mills

- Drills

- Taps

- Reamers

- End mills

4. CNC Router

A CNC router works the same as a CNC mill. However, it is mainly used to work on softer components and is less precise than a CNC mill.

A CNC router is characterized by its capability to use a computer or software program to shape and design materials, such as plastic, composites, foam, steel, and wood.

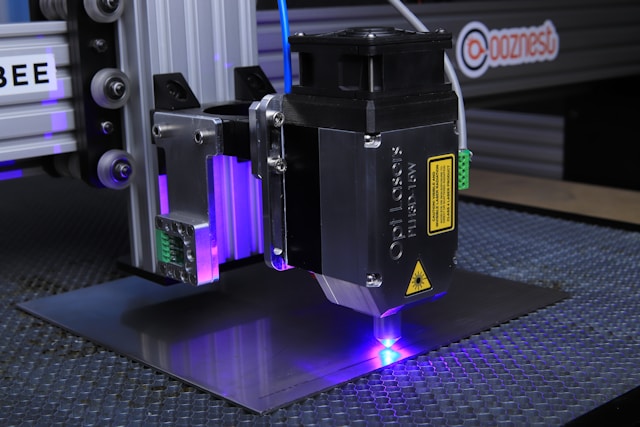

5. CNC Laser Machine

A CNC laser machine has a pointed router. This router comes with a focused laser beam used to engrave, cut, or slice materials precisely. The laser often heats materials and makes them vaporize or melt, thus creating cuts in materials.

This process produces more designs than conventional machines and creates edges or cuts that don’t need more finishing processes.

6. CNC Lathe

This works by simply spinning a workpiece at a very high speed. A cutting tool is often used to create your desired products during the process.

Basically, this machine works best for materials with flat, conical, or cylindrical shapes. This is a unique difference between a CNC lathe and a CNC mill.

While it is considered less versatile and precise than a mill, CNC lathes cost less and are more efficient for simple and quick projects.

While different CNC machines use various tools, a software program directs and controls their actions. As a programmer, machinist, or operator, it is best to know how all these machines work and what they can do to complete a project.